The top challenges in commercial API manufacturing

Once an investigational medicinal product has demonstrated its safety and efficacy during clinical trials, the next challenge for its Sponsor is to secure a reliable supply chain for its commercial production. Understandably, commercial pharmaceutical manufacturing, including commercial API manufacturing, is a highly regulated area to ensure patients’ ongoing access to a consistently high quality of medicines that guarantees their safety and efficacy. Transitioning from a clinical pilot scale to eventually the larger plant scale required for commercial API production can be a long and arduous process.

The main challenges faced in the journey to commercialization include scaling up production, establishing and maintaining process consistency and reproducibility, and ensuring compliance with regulatory guidelines. In this blog, we explore these areas in detail, discussing how a strategic approach, robust planning, and the incorporation of innovative technologies, can help ensure your drug smoothly and successfully reaches the market.

Developing robust and scalable processes

Increasing the production of active pharmaceutical ingredients (APIs) and drug excipients from milligram to multi-kilogram quantities is arguably the biggest challenge faced in paving the way to reliable commercial pharmaceutical manufacturing. Without the adoption of strategic planning during the process development stage, unexpected issues may arise and lead to significant increases in your program timelines and costs.

Here are our top tips for effectively planning and developing robust and scalable API manufacturing processes, and achieving faster and more seamless scale-up that supports marketing approval and supply security requirements:

- Choice of starting materials – several considerations should be made when selecting the starting materials used in the manufacture of APIs and medicinal products. This includes quality, compatibility, long-term stability, affordability, safety, security of supply, and compliance with pharmaceutical regulatory guidelines. Ensuring your starting materials meet these criteria throughout the entire scale-up process, up to commercial scale, will pave the way for a safe and high-quality medicinal product.

- Choice of equipment and processing technology – where possible, scalable equipment and processing technology should be chosen in API and drug manufacturing. This will help to streamline the technology transfer process, reducing the time and costs required for process optimization and validation, and minimizing the risk of failure. Cost, availability, material compatibility, cleaning processes, and the ability to implement automation and control systems at commercial scale should be considered.

- Process development – the basis of every robust, scalable process is effective API process development. This requires the optimization of several components, including the selection of the synthetic route, and measures for process control and risk management. Scientific and risk-based approaches should be utilized to help gain an in-depth understanding of how any changes to the process during scale-up will affect the safety and quality of the product.

Read this blog for more detail on how to optimize API process development

Establishing and maintaining process consistency and reproducibility

Establishing and maintaining consistency and reproducibility during scale-up is a complex yet vital task in commercial pharmaceutical manufacturing. Increasing the vessel size and introducing any other necessary changes can drastically alter process performance and product quality. Failure to design and optimize the process to account for these differences could derail production, altering the safety, quality, and efficacy of the API.

The key to ensuring process consistency and reproducibility in commercial scale production lies in strategic planning during process development, with the use of systematic approaches that facilitate the implementation of a robust process control strategy

Implementation of systematic approaches

Several systematic approaches, such as design of experiments (DoE), quality by design (QbD), and process modeling and simulations performed with a software such as Dynochem® are used to improve knowledge of the product and the scale-up process. This includes the thorough impact assessment of any changes in processing parameters on process performance and final product quality.

DoE involves the use of factorial design to plan a series of experiments that test simultaneously variations in individual input factors. The aim of this is to gain an understanding of the individual and combined effects of parameters variability on the process performance and output. Following these experiments, mathematical models, such as response surface methodology (RSM), are used to identify the optimal set of process parameters as well as the acceptable operating envelope for the process.

DoE and process modeling and simulations can be integrated into a QbD approach, which incorporates statistical and analytical methodologies to enhance the process control strategy and build quality and risk management into the manufacturing process. This is achieved by identifying the critical process parameters (CPPs) and critical quality attributes (CQAs) that are associated with the quality, safety, and efficacy of the drug substance and excipients.

Using the QbD methodology, the determined parameters and quality attributes are used to establish a design space. For this, statistical tools are used to explore how combinations of CPPs might interact and impact on CQAs. This helps manufacturers optimize the production of APIs and drug excipients, ensuring the design of reproducible processes that minimize batch failure risks and significantly reduce batch-to-batch variability.

Click here to learn more on how to apply QbD principles to drug development and manufacturing

Adoption of advanced process control systems

The process knowledge gained from experimental modeling approaches, such as QbD and DoE, can be used to develop advanced process control systems. These commonly utilize process analytical technology (PAT), which monitors process parameters on-line in real-time.

When PAT is integrated into advanced process control systems, the analytical data may be used to make automatic system adjustments and maintain process parameters within their predefined limits. This reduces manual intervention and creates a closed-loop control system, allowing for the immediate detection of deviations in process conditions and subsequent feedback control.

By immediately correcting any deviations in the process, advanced process control systems enable real-time release testing, assuring manufacturers that the processes have remained consistent, and that the product meets quality and safety standards. By increasing efficiency and consistency, these systems also help to reduce waste, costs, and product cycle times.

Regulatory compliance

Compliance with current good manufacturing practice (cGMP) regulations is critical to ensuring the production of consistent, high-quality, pharmaceutical products. API manufacturing plants are subject to strict regulations, with complex and ever-evolving requirements, stringent quality standards, and severe consequences in case of non-compliance. To comply with cGMP guidelines, several robust management systems must be in place, including those for data integrity, process control, risk management, and supply chain management:

Data integrity

Consistent, accurate, timely, and complete records are required to provide regulators and stakeholders with the confidence that your medicinal product meets all safety and quality standards. Clarity, consistency, and conciseness of the documents must be maintained across the entire product lifecycle. The development of a robust documentation system can help manufacturers with this, establishing effective procedures for naming, authoring, reviewing, approving, updating, storing, and distributing documents.

Control strategy

There are increasing requirements for a clear, well-defined, and scientifically justified process control strategy in cGMP applications. This should include the selection and evaluation of starting materials, followed by approaches including QbD and DoE to link materials attributes and process parameters to product CQAs. These approaches are used to establish a design space and plan control measures to ensure that CQAs are met and a sound process validation methodology is implemented. Furthermore, the process control and validation strategy should be adapted to the increased production scale throughout all stages of the product’s lifecycle.

Risk management strategy

cGMP guidelines require a systematic approach to risk assessment in pharmaceutical manufacturing. This involves the process of identifying, assessing, controlling and reviewing risks based on their potential for impacting the performance of the process and the quality of the product. Risk management plays a central role in scaling up to commercial production in order to mitigate significant quality risks such as cross-contamination and minimize health and safety risks to operators, especially when handling highly potent APIs. Several tools are available for risk assessment, including failure mode and effects analysis (FMEA).

Supply chain management systems

In the pharmaceutical industry, securing patients’ access to drug supplies post-marketing authorization is a regulator’s number one priority. Regulatory guidelines are designed to cover the entire supply chain, from the supply of raw materials to be introduced in cGMP manufacturing operations through to the manufacturing, packaging, labeling, and distribution of the final product.

Digitalizing the management of manufacturing activities can enhance the visibility and efficiency of inventory management, product monitoring, and data exchange throughout the supply chain. Additionally, supply chain management systems should be designed to incorporate risk management strategies for the prediction, prioritization, and mitigation of risks of product stock-outs. This is not only essential for regulatory compliance and patient access, but it will also increase supply chain efficiency to help overcome issues such as inadequate forecasting, long lead times and build-up of working capital.

How to master commercial pharmaceutical manufacturing

The journey to commercialization can be challenging. Scaling up production while maintaining process consistency, product quality, and regulatory compliance, requires expert process development capabilities, and the adoption of innovative science and risk management methodologies. A common pitfall for the Sponsor of an innovative therapy is to under-estimate the complexity and intricacy of this enterprise, which involves the coordinated optimization of strategies for process control, risk management, data management, and supply chain management.

With ever-evolving regulatory requirements and the increasing urge to shorten drug development timelines, getting your drug to market can seem like a daunting undertaking. That’s why taking some of the pressure off your organization by outsourcing your drug development and manufacturing activities to an expert partner can be the smartest decision. This will ensure your drug is commercialized in the fastest and most cost-efficient way possible, utilizing expertise, facilities, equipment, and processes to anticipate and overcome any challenges thrown at your program with ease.

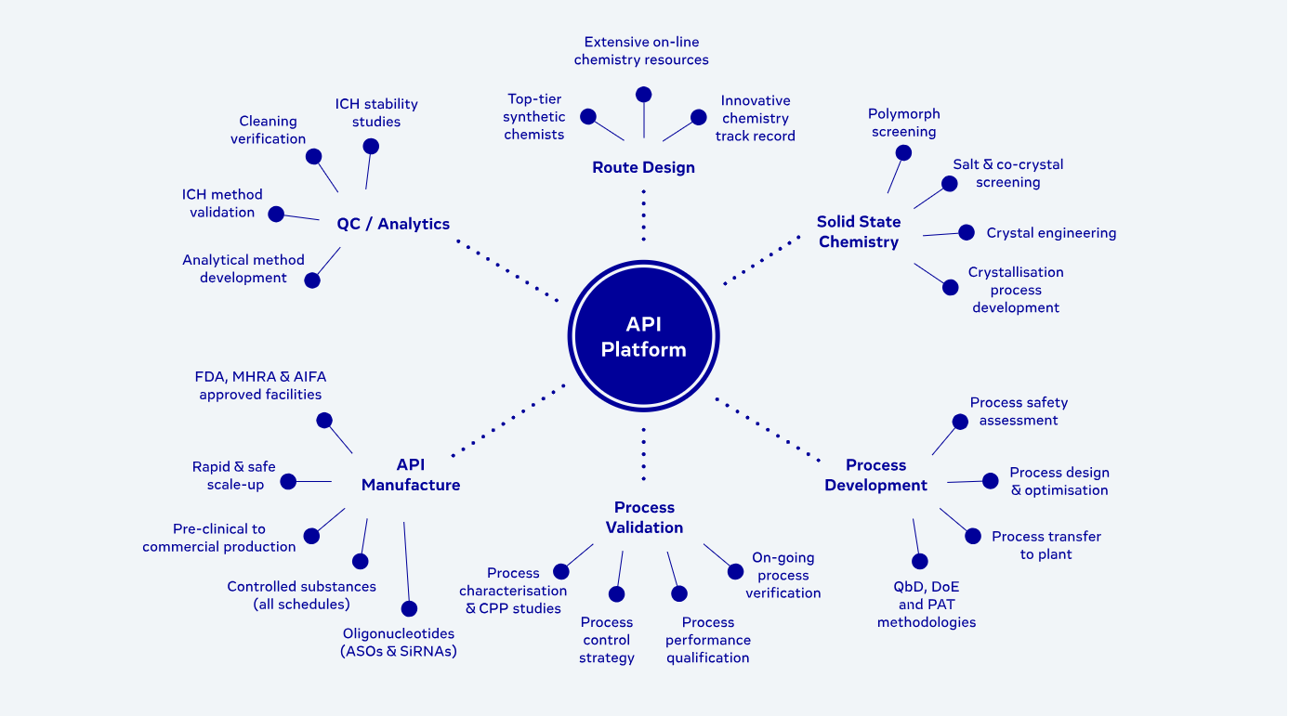

Evotec offers an integrated end-to-end solution for innovative drug R&D, with the capabilities to support all phases of your drug development program. Your projects are in safe hands with our team of expert scientists who are pioneers in QbD, process design, scale-up, and validation, operating to full cGMP within FDA, MHRA, AIFA and BfArM approved facilities.

|

Our chemistry, material science, analytical, and manufacturing operations are co-located at sites in Abingdon, UK, Verona, Italy, and Halle/Westfalen, Germany, with more than 25 years of experience in the development and manufacturing of small molecule APIs. Alongside integrated process research and analytical development, Evotec supplies APIs for use in pre-clinical development, non-clinical use, clinical trials, and low volume commercial supply.

|

|

Learn more about our API and drug product manufacturing capabilities