With the ASAPprime® tool at Evotec and our dedicated experts, swift data interpretation and precise drug product shelf-life estimation are no longer challenges, but a seamless reality.

With the ASAPprime® tool at Evotec and our dedicated experts, swift data interpretation and precise drug product shelf-life estimation are no longer challenges, but a seamless reality.

Tags: Infographics, Formulation & CMC, IND Enabling Studies/Preclinical Development

Download the highlights from our DCAT presentation to learn how continuous biomanufacturing reduces the environmental impact of antibody production.

The continuous manufacturing of therapeutic antibodies in agile facilities with a small cleanroom footprint allows:

Just-Evotec Biologic's unique continuous biomanufacturing platform for antibody therapeutics and innovative J.POD facility design are reducing manufacturing costs and increasing the sustainability of bioproduction.

View the presentation to learn more!

Tags: Presentations, Formulation & CMC, Biologics

Enhancing Single-Pass TFF for Antibody Therapeutics Manufacturing

Single-Pass Tangential Flow Filtration (TFF) plays a pivotal role in enabling fully end-to-end continuous manufacturing of antibody therapeutics. In this poster, we delve into the study of two distinct SP-TFF membrane configurations to determine which one is most effective for clinical and commercial production.

Key Findings:

1. Concentration Factor Achievement: Both tested configurations successfully achieved the required concentration factor without encountering fouling issues.

2. Shear Forces Mitigation: Neither setup generated significant shear forces that could harm the antibody product.

3. Operational Success at Low Feed Flux: Both configurations demonstrated successful operations even under low feed flux conditions, reinforcing their suitability for large-scale manufacturing.

Future Directions: Our team of scientists and engineers will continue their investigation, exploring various load challenges, system perturbations, and methods for in-line concentration measurements. These efforts aim to enhance the robustness and efficiency of our manufacturing processes.

Tags: Posters, Formulation & CMC, Biologics, Clinical Development

The Twin Screw Wet Granulation (TSWG) is a manufacturing process gaining increased attention in the pharmaceutical industry due to its versatility, scalable nature, and seamless integration into continuous manufacturing lines. Especially advantageous in early pharmaceutical development, where API quantity is limited, TSWG accommodates small batch sizes, facilitating later large-scale campaigns using the same equipment.

A DoE study was conducted in order to assess the influence of the main process parameters on the characteristics of granules and tablets. A leading formulation containing a soluble drug, namely Niacin, was used, and the factors evaluated in the DoE were the screw design, the screw speed, the Liquid/Solid ratio (L/S), the feed rate and the screen type.

The responses evaluated were referring to the process (e.g. torque), the granules (e.g. particle size distribution (PSD), density and flowability) and the tablets (e.g. tensile strength, friability and disintegration time). This study provides critical insights into optimizing TSWG processes, ensuring efficient granule and tablet outcomes.

Download the poster, which was presented at AAPS PharmSci360 2023, for comprehensive details on the influential process parameters and their impact on granulation and tablet characteristics in TSWG.

Tags: Posters, Formulation & CMC, IND Enabling Studies/Preclinical Development

This text underscores the significance of Orally Dispersible Tablets (ODTs) for enhancing treatment compliance, particularly for patients with swallowing difficulties. Co-processed excipients for fast-disintegrating tablets (CPE-ODT) offer a convenient solution, combining a soluble filler and superdisintegrant. These can be efficiently blended with active ingredients, lubricants, and compressed into tablets, streamlining the development process. Investigating the relationships among compaction stress, compact solid fraction, and mechanical strength is crucial for optimizing tablet composition and speeding up development. Striking a balance between inter-particle bonding strength and porosity is especially vital for ODTs, ensuring rapid disintegration with sufficient mechanical resistance for downstream processes. The study aims to establish a general pre-formulation screening method by generating compressibility, compactibility, and tablettability profiles of CPE-ODTs blended with varying drug amounts. These data offer valuable insights into the impact of drug load on compression behavior and key properties, such as friability and disintegration time, facilitating the efficient development of ODTs.

Download this poster presented at AAPS PharmSci360 2023 for comprehensive details on this formulation screening approach.

Tags: Posters, Formulation & CMC, IND Enabling Studies/Preclinical Development

This poster discusses the development of oral enteric dosage forms as a solution to bypass the acidic stomach environment. Coated hard-shell capsules are more time and cost-efficient in early pharmaceutical development than enteric tablets and pellets. The current study assesses acid-resistance and dissolution rate of not-banded gelatin and HPMC capsules, filled at two weights, and coated with an enteric polymer at four levels. The goal is to determine the minimum enteric polymer needed for gastro-resistance, compare gelatin and HPMC shells in the coating process, and examine the impact of filling level and curing step on dissolution profiles, with fixed coating parameters. This research is important for optimizing the coating process and advancing the understanding of factors influencing gastro-resistance in oral enteric dosage forms.

Download our poster presented at AAPS PharmSci360 2023 for in-depth insights into this critical aspect of pharmaceutical development.

Feel free to make questions to our experts!

Tags: Posters, Formulation & CMC, IND Enabling Studies/Preclinical Development

While simple combinations of dosage forms expedite access to First-in-human (FIH) studies, the demand for robust formulations and processes challenges quick development, particularly for tablet production. Early clinical phases face hurdles like dose uncertainty and limited active pharmaceutical ingredient availability. The study addresses these challenges by proposing a compressibility assessment method using small-scale experiments. The aim is to establish a pre-formulation screening approach based on compressibility data for active ingredients, utilizing round punches of varying diameters. By employing the smallest tooling, the study achieves a remarkable 75% reduction in the amount of active ingredient required for compressibility analysis.

Download our poster presented at AAPS PharmSci360 2023 to learn more

Tags: Posters, Formulation & CMC, IND Enabling Studies/Preclinical Development

Check out Evotec's infographic to learn more about our expertise with ASAP as well as with all-type stability studies.

Tags: Infographics, Formulation & CMC, IND Enabling Studies/Preclinical Development

Check out Evotec's infographic on Aerodynamic Particle Size Distribution and learn how our dedicated team of scientists has the right experience in analytical inhalation to ensure accuracy and reliability.

Tags: Infographics, Formulation & CMC, IND Enabling Studies/Preclinical Development

Targeting RNA represents a paradigm shift for drug discovery. The ability to seek out and destroy, or change, a faulty RNA template, before the toxic protein has even been made, has only recently begun to be harnessed for the benefit of patients.

As of this blog, only 16 oligonucleotide drugs have been marketed, with an exponential increase in clinical trials and development exploding in this area.

There exist different mechanisms of action for an oligonucleotide drug, all of which are transient and reversible effects and do not include alteration of the DNA, unlike Gene therapy.

Antisense Oligonucleotides harness endogenous systems already existing within a cell to achieve their purpose, with the only limitation being accessibility of the target tissue. Once bound with great specificity to its RNA target, a short synthetic oligonucleotide can cause degradation, upregulation of the translated protein, or alteration of a splicing event leading to correctly folded protein. Longer Oligonucleotides can fold into 3 dimensional shapes called Aptamers with similar target affinities and applications as antibodies, and shorter oligonucleotides can act as miR mimetics or antagonists to alter multiple targets or pathways at the same time with subtle but broader effect.

The precision accuracy of an oligonucleotide and its ability to correct a faulty RNA produced by an error in the genetic code, lends itself to the rare disease therapeutic area and toxic gain of function mutations. The field of oligonucleotide therapeutics is moving to address this as a whole and to innovate a new preclinical and regulatory path that could be adapted for these more unique diseases to make this type of therapy more accessible.

Evotec is a leader in integrated Research and Development (EVOiR&D) and has built substantial drug discovery expertise and technical capabilities that can drive new innovative, diverse modalities into the clinic. In addition, Evotec has built a deep internal knowledge base in key therapeutic areas including neuroscience, pain, immunology, respiratory, women’s health, aging, fibrosis, inflammation, oncology, metabolic and infectious diseases. Leveraging these skills and expertise, Evotec successfully delivers on superior science-driven discovery alliances with pharmaceutical and biotechnology companies.

The global interest in this new modality area has led to high demand in oligonucleotide synthesis and the chemistry surrounding it, such as covalent linkages and complex formulations. Evotec has oligonucleotide manufacturing capabilities as well as ligand and linker chemistry expertise to support discovery projects and is now expanding its capacity to support development stage oligonucleotide projects.

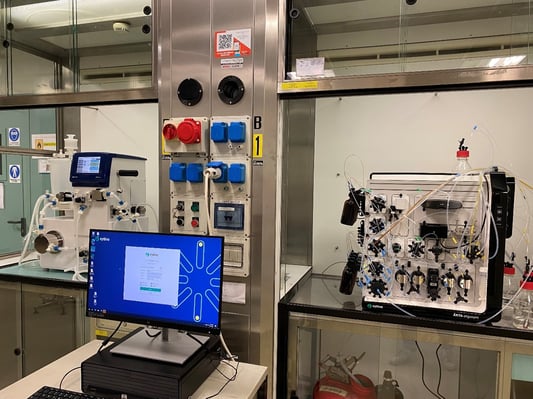

We are extremely proud to share that we have installed the first Cytiva AKTA oligosyntTM in Europe at our Evotec site in Verona.

This new state of the art equipment will allow for the synthesis of complex modified oligonucleotides (ASOs, siRNAs etc) on a scale from 0.5 to 50 g (up to 12 millimoles) to support the initial preclinical development studies.

This is a key milestone for Evotec, and, together with the brand-new AKTA flux 6 and AKTA Pure 150, this new oligonucleotide synthetiser will complete the fully integrated oligo suite Evotec Campus Levi-Montalcini in Verona. Currently both the Verona and Toulouse Evotec sites are equipped to support Drug Discovery programmes in the RNA therapeutics field with the synthesis of oligonucleotides on a research scale and now, Evotec, at the Verona site, has the capability to also support the preclinical and clinical development studies, i.e. analytical and bioanalytical activities.

We look forward to discussing with you – our partners from new or existing collaborations- how we can best help your oligo project succeed.

Tags: Medicinal Chemistry, Blog, Formulation & CMC, IND Enabling Studies/Preclinical Development, Toxicology & Safety